Your Online HERS Rater Training Center

FREE HERS RATER PRACTICE EXAMPUT YOUR HOME PERFORMANCE BUSINESS ON ROCKET FUELENERGY AUDITOR NEWSLETTERGet the only Energy Auditor Marketing Newsletter with monthly strategies and tactics to grow your home performance business.

|

BPI Written Exam - Section 1 Building Science Fundamentals5. Understand area weighted R-Value

The area weighted R-value is for finding the R-value of a series of materials together as one. It is most often used when calculating a walls R-value because it considers multiple materials such as drywall, vapor barriers, siding and wall studs, not only the insulation in the walls. This may be a problem you see on the BPI test, so here is what you need to know.

Terms:

Relationship between U-value and R-values U-values are the fraternal twins of R-values, meaning that to find a U-value for a material, simply put 1 over the R-value = U-value. The opposite is true also, to find the R-value of a material given the U-value, take 1 over the U-value = R-value.

The difference between R-value and U-value

Practice Problem:

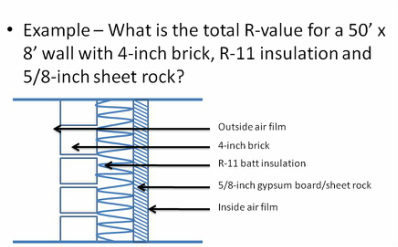

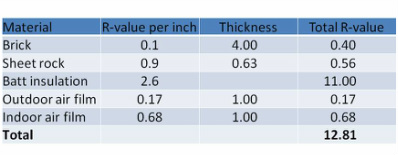

Find the R-value of this made-up, all-insulation and no stud wall, given the following: R-values –Brick = R-0.10 per inch –Sheet rock = 0.90 per inch –Batt insulation = 2.6 per inch –Outdoor air film = R-0.17 –Indoor air film = R-0.68 First create a table of 4 columns of material, R-value per inch, Thickness and Total R-value.

Then you can multiply all the R-values by their thickness to get the total R-value for each material. Before going further, try it on your own an see if your number matches mine. In homes and buildings, walls are not all just insulation. We need to account for the studs and other materials as well.

On the test:

What BPI will give you:

Approach:

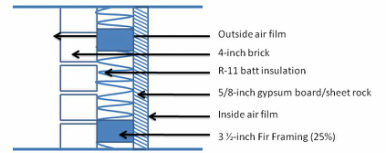

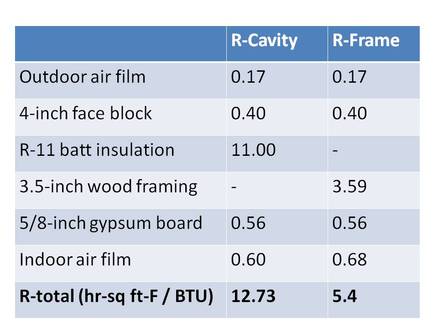

Here is another sample problem you may see on the BPI test to find the R-value of the wall composition. Follow the approach above with your 4 columns. Once you've added the total R-values for all the wall components, remember to multiply the cavity and frame by 75% and 25% respectively.

Next Section1a. Basic terms and definitions

1b. Principals of energy, air & moisture

1c. Combustion science

|