Your Online HERS Rater Training Center

FREE HERS RATER PRACTICE EXAMGET THE NEWSLETTERTo get FREE updates and information about all the BPI Exams, please enter your name and email below.

|

Combustion Appliance Zone (CAZ): Depressurization, Spillage, Draft, Carbon Monoxide (Ambient and Flue)CAZWe need to test and

check if conditions in the home can create backdrafting, spillage or flame rollout. CAZ pressures may overcome the draft pressure needed to safely exhaust hot water tanks and furnaces. To create worst case conditions, we should turn on every device that can create a negative pressure in the house and then measure the negative pressure created where the

combustion appliance is located and compare that pressure to the outside (aka WRT outside).

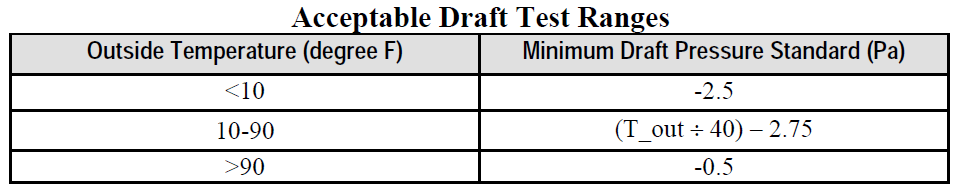

DraftDraft test tells us the pressure difference between the two ends of the flue

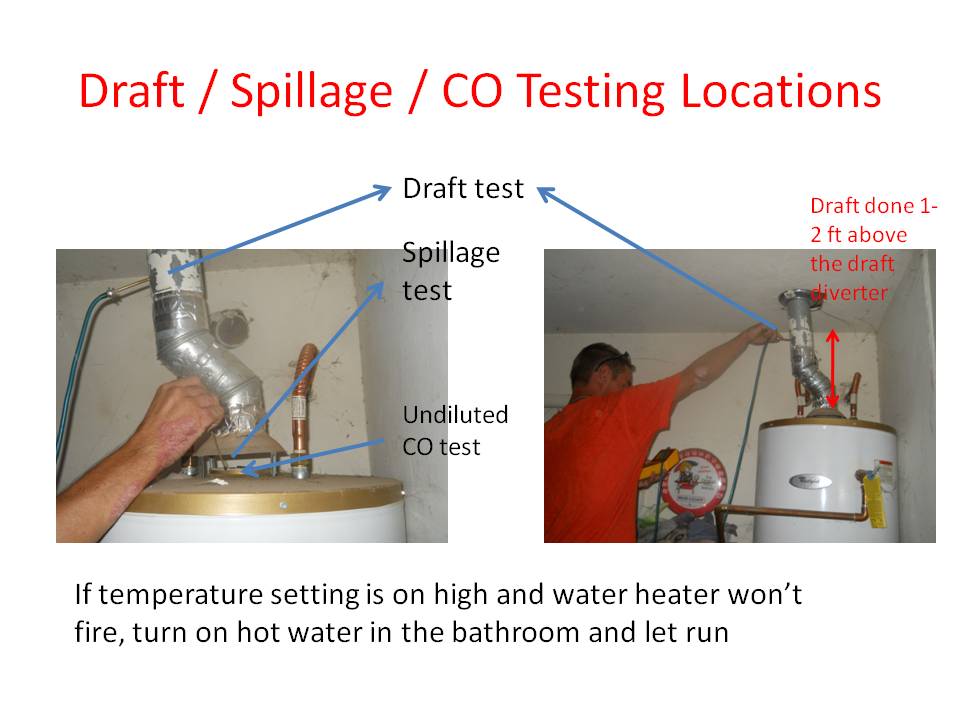

Input A: With the water heater / atmospheric furnace turned on, measure the flue draft with the hose connected to the draft probe and record draft after appliance is fired up within the first minute of operation. Drill your hole between 12-inches and 24-inches from the top of the diverter on naturally vented appliances BPI standards

DepressurizationDepressurization does not just happen to a home when you run your blower door, it happens under natural conditions as well. Think about when you have your exhaust vans running, kitchen range hood, dryer and central vacuum system… those are all mini blower doors running on depressurization. What about natural draft chimneys and the stack effect of warm air rising and sucking in cooler air from the house… that’s depressurization. Or finally on a windy day when one side of a house is getting hit with wind, what is happening to the other side of the house? It’s sucking the air from the house which is the same as depressurization. And the danger of depressurization is back drafting of CO into the home, so it’s something we want to avoid and is why we put the home under worst case conditions with all the fans on and doors closed. We are trying to make the house fail and spill CO into the home while we are there, under controlled conditions so we can recommend and fix the problem.

SpillageSpillage occurs when combustion gases spill out of a gas appliances’ flue and into the home. This could happen because of depressurization as mentioned above, or because something is blocking the flue pipe. Sometimes bird like to keep warm on the flue and block one side of it, or it could be clogged with twigs from their nest. We can test spillage with a smoke pen, going 360 degrees around open diverters of water heaters and furnaces. If at any point, the smoke from the pen or incense stick does not go up the flue, the appliance has failed the spillage test and further remediation needs to be taken.

Carbon Monoxide (CO): AmbientOne of the quickest ways to fail the BPI field exam is to forget to turn on your ambient CO meter before you walk in the house. A CO monitor like the one shown below should be on from the moment you leave your car to walk across the front sidewalk. The ambient CO meter tells you the presence of the deadly

gas carbon monoxide (not the same as carbon dioxide, which is harmless) by a

series of beeps. The more frequent the

beeps, the more CO is in the air and per BPI Standard if the ambient CO level

ever gets above 35 ppm, you need to evacuate the home immediately and open the

windows to ventilate the home. You must

stop your evaluation until the problem has been fixed, then and only then can

you continue retesting the home.

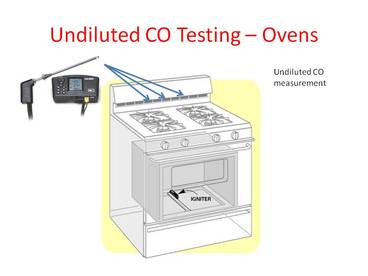

Carbon Monoxide (CO): FlueCarbon monoxide is formed from the incomplete combustion of carbon dioxide. CO is deadly and needs to be measured in all gas appliances. Combustion appliances with power vents like an 80% AFUE furnace can have the CO measured at the outlet terminal (outside). Combustion appliances with open draft diverters (you can stick your fingers in the diverter) should have an undiluted CO measurement taken. In ovens, this is in the throat of the flue as shown below.

Next Section3a. Applied diagnostics and troubleshooting

|